?Animal hair, poultry feathers and other keratin-containing waste is usually dumped, sometimes landfilled, and incinerated. This process is followed throughout the world. But such action leads to pollution of soil, water, and air. Such waste, like feather, also causes many diseases in human.

New Techniques To Turn Poultry Feather & Animal Hair To Fertiliser

Indian scientists have developed a new sustainable and affordable solution for converting keratin waste to fertilisers and animal feeds

India too generates a huge amount of human hair, animal hair, poultry feather waste, and wool waste each year. These wastes increase environmental hazards, pollution, and poses a threat to public health, and also increase greenhouse gas emissions.

But now there is good news for poultry and livestock farmers. Indian scientists have developed a new sustainable and affordable solution for converting keratin waste to fertilisers and animal feeds.

These wastes are inexpensive sources of amino acids and protein – underlining their potential to be used as animal feed and fertiliser.

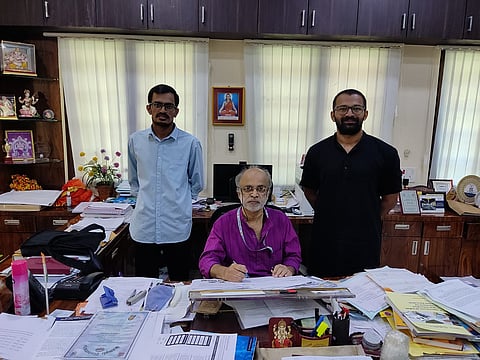

“Every keratinous waste can be treated to make fertilisers. In fact, from chicken feathers, we’ve been able to isolate a pure protein which can be consumed as supplement by human beings,” said Professor A. B. Pandit, Vice-Chancellor, Institute of Chemical Technology Mumbai.

Professor Pandit, along with his students, has developed a technology to covert the keratin waste to food for pets and fertilisers for plants with the support from the ‘Waste Management Technology’ programme of the Department of Science and Technology, Government of India.

This novel technology is patented, easily scalable, environment-friendly, energy-efficient, and will make amino acid-rich liquid fertilisers more economical as compared to currently marketed products.

The time required for the process depends on the type of product needed.

“If the product required is either animal feed or fertilisers, it takes about six to eight hours. If you wish to isolate the specific protein out of it, then there are additional two-three steps involved. If you want to separate the amino acids from the protein, then there are other steps required to be followed… There is value addition in each of those steps,” explained Professor Pandit.

His team used advanced oxidation for the conversion of the waste to marketable fertilisers and animal feed. The key technology behind this involves pre-treatment followed by hydrolysis of keratin using a technique called Hydrodynamic Cavitation, which involves vaporisation, bubble generation, and bubble implosion in a flowing liquid.

“The cost of isolating protein in pure form – that can be used as protein supplement for human consumption – is working out to about Rs. 120-150 per kg,” said Professor Pandit.

“Compare that to the price of protein supplement available in the market for around Rs. 700-800 for a kg,” added the innovator.

The current chemicals, and the physical methods for such conversion are energy-intensive, chemically hazardous, and involve multiple steps – resulting in a higher cost of the final product. As calculated by the team, with this technology, the cost of the product at a large-scale plant is up to three folds cheaper than the existing market product.?

The scientists are currently implementing this technology at a large scale in collaboration with Revoltech Technologies Private Limited, Gujarat. This advancement in production will make the liquid biofertilizers which more efficient than the marketed product, available to farmers at an affordable rate.

“It works out to be extremely economical. Even liquid fertilisers can be sold for Rs. 15-20 a litre,” claimed the Vice-Chancellor.

“The nitrogenous fertilisers are easily digestible by plants. Here you have natural fertiliser when the world is trying to move away from synthetic products due the hazards,” he added.